Exploring the most up to date Developments in Woodworking Machinery for Boosted Workmanship

The woodworking sector is going through significant change because of recent improvements in machinery. Innovations such as clever saws, CNC equipments, and laser cutters are redefining accuracy and performance (Lumber Stacker). These tools not only boost craftsmanship but likewise promote safety and tidiness in the work area. As innovation integrates with traditional methods, a brand-new degree of creative thinking emerges. The ramifications of these advancements elevate questions regarding the future of woodworking and the potential for even better technologies ahead

Smart Saws: Precision Reducing for Every Timber Kind

In recent times, numerous innovations in woodworking equipment have actually emerged, with wise saws leading the method in accuracy cutting for different wood kinds. These sophisticated devices utilize digital modern technology to boost precision and efficiency, enabling woodworkers to attain precise cuts with minimal effort. Equipped with sensors and automated systems, clever saws can automatically readjust setups based on the kind and thickness of the wood, making certain peak performance for every project.

CNC Machines: Bringing Intricate Designs to Life

CNC devices represent a significant advancement in woodworking technology, enabling artisans to bring complex layouts to life with impressive accuracy. These computer-controlled tools make use of advanced software application to analyze digital designs and execute complex cuts and carvings, reducing human mistake and optimizing performance. With the capacity to collaborate with numerous products, including compounds, softwoods, and hardwoods, CNC machines provide to diverse woodworking tasks, from furnishings making to complex kitchen cabinetry.

Craftsmen can produce detailed patterns and forms that would certainly be labor-intensive or nearly difficult to achieve with traditional devices. The convenience of CNC devices additionally enables rapid prototyping, making it possible for designers to evaluate and improve their concepts promptly. Because of this, these equipments not just improve craftsmanship however also broaden the creative opportunities within the woodworking sector. By incorporating accuracy and modern technology, CNC equipments have actually changed the way artisans approach their craft, establishing brand-new standards for top quality and style.

Laser Cutters: Enhancing Information and Performance

While several woodworking tools enhance efficiency, laser cutters stand apart for their capacity to deliver phenomenal detail and efficiency. These innovative machines make use of focused laser beam of lights to puncture wood with unmatched precision, enabling artisans to produce intricate layouts that traditional approaches can not accomplish. The blog rate at which laser cutters operate considerably decreases production time, allowing artisans to tackle even more projects without giving up quality.

Laser cutters also use versatility, fitting numerous products past wood, such as composites and acrylics. This versatility enables services to diversify their offerings and interest a broader clients - Woodworking Machinery Products. Furthermore, laser technology reduces waste by making cleaner cuts, which is both affordable and eco-friendly

As woodworking remains to evolve, the integration of laser cutters represents a significant development, empowering artisans to push the boundaries of creative thinking and efficiency in their job. This technology notes a critical change in the woodworking market, enhancing both creativity and performance.

Dust Collection Solutions: Keeping a Tidy Office

As woodworking projects generate substantial amounts of dirt and particles, efficient dust collection systems play a vital function in keeping a secure and clean work space. These systems are made to catch and remove particulate matter produced throughout cutting, fining sand, and milling processes, therefore improving air high quality and decreasing the danger of breathing concerns for craftsmen.

Modern dust collection systems use innovative innovation, consisting of whirlwind separation and high-efficiency filters, to take full advantage of dirt extraction efficiency. Numerous systems can be integrated with existing machinery, enabling for seamless operation and reducing setup time.

Furthermore, mobile dust collectors supply adaptability for varying job sizes and areas, making sure that woodworkers can maintain sanitation regardless of office restraints. Executing a robust dust collection system not just boosts the total woodworking experience but likewise extends the life of devices and equipment by protecting against dirt buildup. Investing in high quality dust collection is important for any kind of significant woodworker.

Digital Style Software Program: Enhancing the Creative Refine

Additionally, several software alternatives integrate seamlessly with CNC devices, enabling for automatic production based on digital designs. This combination of technology and craftsmanship not just accelerates the fabrication process but also encourages woodworkers to discover cutting-edge styles without the restrictions of standard strategies. Ultimately, digital layout software visit this site right here program is improving woodworking, promoting a new era where creative thinking and innovation exist together harmoniously

Regularly Asked Concerns

What Are the Upkeep Needs for Modern Woodworking Machinery?

Modern woodworking equipment needs normal cleaning, lubrication of moving components, evaluation for deterioration, tightening of loose parts, and routine calibration to assure peak efficiency and long life, adding to total efficiency and security during procedures.

Exactly how Do I Pick the Right Equipment for My Workshop Size?

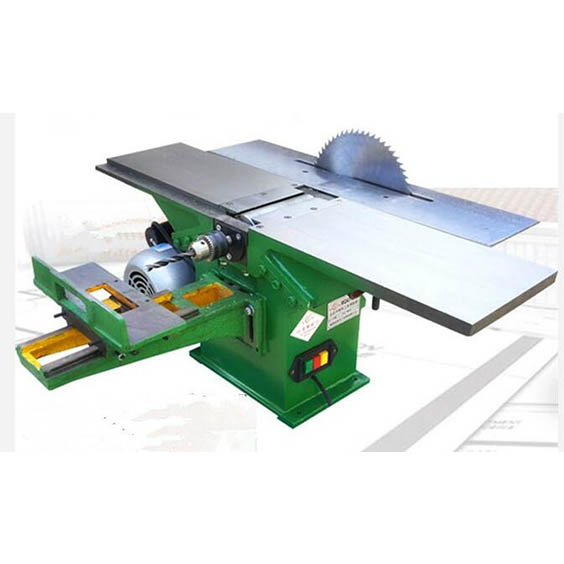

To pick the appropriate equipment for a workshop size, one need to examine offered room, take into consideration the device's footprint, examine power needs, and focus on multifunctional tools for performance, guaranteeing compatibility with the desired woodworking tasks.

Are There Security Functions in New Woodworking Machines?

Numerous new woodworking makers include advanced safety and security functions, such as automated shut-off systems, blade guards, and emergency situation quit buttons. These enhancements intend to secure users and lessen accidents, promoting a much safer working atmosphere for artisans.

What Is the Typical Life-span of Woodworking Equipment?

The average lifespan of woodworking machinery commonly ranges from 10 to 20 years, relying on usage, maintenance, and the quality of the maker. Normal upkeep can especially extend its operational performance and durability.

How Can I Financing the Acquisition of Woodworking Tools?

Funding woodworking tools can be accomplished via different means, including individual finances, equipment funding alternatives, leasing contracts, or making use of bank loan. Examining one's spending plan and researching funding sources is crucial for educated decision-making.

As a result, these devices not only improve workmanship but likewise broaden the imaginative opportunities within the woodworking industry. Executing a robust dust collection system not just boosts the overall woodworking experience but likewise prolongs the life of devices and equipment by stopping dirt buildup. In parallel, electronic design software has emerged as a crucial device in the woodworking industry, substantially streamlining the creative process. Lots of brand-new woodworking equipments include innovative safety and security functions, such as automatic shut-off systems, blade guards, and emergency stop switches. The ordinary lifespan of woodworking equipment normally ranges from 10 to 20 years, depending on usage, maintenance, and the quality of the maker.